Microfiber Leather Surprises with Its Eco-Friendly Power

Aug 28, 2025

Microfiber leather stands out as an eco-friendly alternative to traditional leather. Many manufacturers now use recycled polyester and water-based polyurethane coatings, which help reduce chemical emissions and energy use. As an animal-free material, microfiber leather supports biodiversity and avoids the ethical concerns of genuine leather. Faux Leathers offers innovative microfiber solutions that combine durability and style. Compared to both traditional and vegan leather, microfiber provides a versatile, sustainable option for consumers who want to make responsible choices.

Highlights

Microfiber leather is an eco-friendly alternative to traditional leather, made from synthetic fibers and water-based polyurethane.

This material supports animal welfare by being completely animal-free, appealing to consumers who prioritize ethical choices.

Microfiber leather production uses significantly less water and energy compared to genuine leather, reducing its environmental impact.

The durability of microfiber leather means products last longer, leading to less waste and fewer replacements over time.

Microfiber leather is versatile, suitable for various applications including fashion, automotive interiors, and home furnishings.

Many manufacturers, like Faux Leathers, use recycled materials in microfiber leather production, further enhancing its sustainability.

Microfiber leather is recyclable, supporting a circular economy and reducing landfill waste when products reach the end of their life.

Certifications ensure that microfiber leather meets safety and environmental standards, giving consumers confidence in their purchases.

What Is Microfiber Leather?

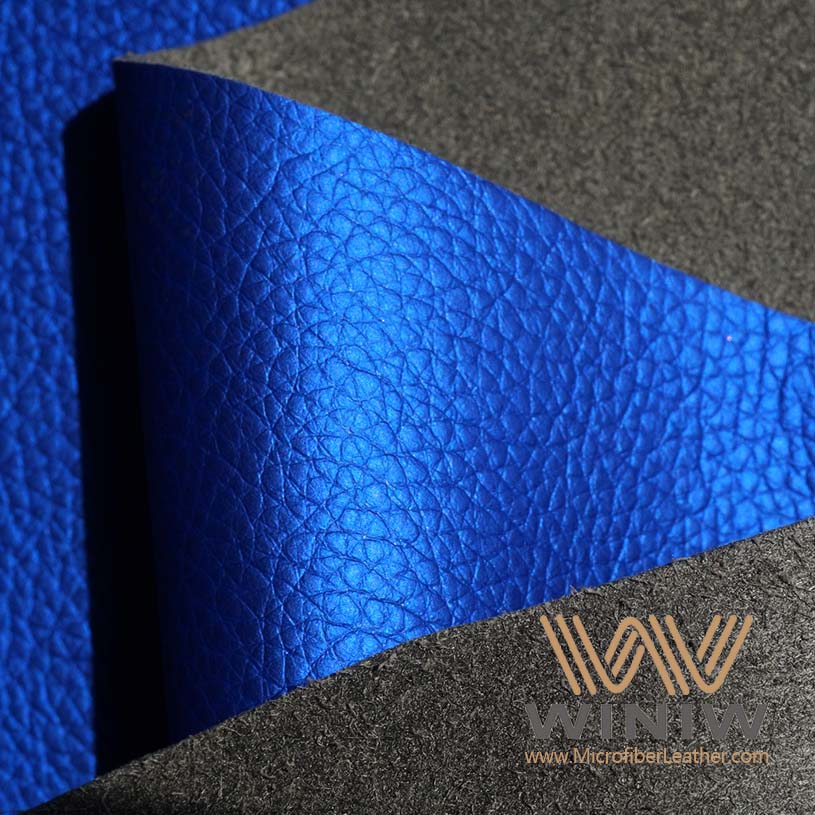

Microfiber leather represents a modern advancement in the world of synthetic materials. Manufacturers designed this material to closely resemble genuine leather in appearance and texture. Faux Leathers offers microfiber synthetic leather that combines durability, versatility, and eco-friendly qualities. This material stands out because it avoids animal products and uses innovative production methods that reduce environmental impact.

Composition

Microfiber synthetic leather consists of two main layers. Each layer plays a vital role in the performance and sustainability of the material.

Synthetic Fibers

The base layer of microfiber synthetic leather uses ultra-fine synthetic fibers, often made from polyester or nylon. These fibers are tightly woven to create a strong, flexible foundation. The structure of the microfiber mimics natural collagen fibers found in animal hides. This design gives the material excellent resistance to wear and tear. Manufacturers choose synthetic fibers because they offer consistent quality and help reduce resource consumption.

PU Layer

A polyurethane (PU) coating forms the top layer of microfiber synthetic leather. This layer provides the material with its smooth, leather-like surface. The PU layer enhances the material’s resistance to scratches, stains, and fading. It also allows for a wide range of colors and textures, making the material suitable for many applications. The combination of synthetic fibers and PU creates a material that is both lightweight and easy to clean.

Tip: Microfiber synthetic leather’s layered structure makes it more durable and versatile than many other synthetic materials.

How It's Made

Manufacturers produce microfiber synthetic leather through a multi-step process. They begin by weaving tiny synthetic fibers into a dense, non-woven fabric. This fabric forms the base of the material. Next, they apply a polyurethane coating to the surface. The PU layer is often water-based, which helps reduce chemical emissions and energy use during production.

The manufacturing process for microfiber synthetic leather avoids the use of toxic chemicals and does not generate greenhouse gases. It requires less water and energy compared to traditional leather production. This approach supports environmental sustainability and aligns with the values of brands like Faux Leathers.

Type of Leather

Raw Materials

Structure and Process

Uses

Microfiber Leather

Synthetic fibers, polyurethane

Non-woven microfiber base, PU coating

Shoes, furniture, handbags, sports

Genuine Leather

Animal hides

Tanned and processed animal skin

Footwear, upholstery, accessories

Synthetic Leather

Synthetic fiber non-woven fabric, polyurethane

Impregnated non-woven fabric, microporous polyurethane grain layer

Shoes, bags, accessories

Microfiber synthetic leather differs from genuine leather and other synthetic leathers in several ways:

Microfiber leather uses synthetic fibers and a PU layer, while genuine leather comes from animal hides.

The structure of microfiber synthetic leather mimics natural collagen fibers, giving it superior durability.

Microfiber synthetic leather is used in a wider variety of products due to its versatility and eco-friendly properties.

Microfiber synthetic leather offers a sustainable alternative to traditional materials. Its composition and manufacturing process help reduce resource consumption and environmental impact. Brands like Faux Leathers continue to innovate, providing high-quality microfiber leather for many industries.

Eco Benefits

Resource Savings

Water Use

Microfiber leather production uses much less water than traditional leather tanning. Genuine leather requires large amounts of water for soaking, washing, and dyeing animal hides. Microfiber leather, on the other hand, relies on synthetic fibers and polyurethane coatings, which need far less water during manufacturing. Many producers also use recycled materials, further reducing the environmental impact.

Microfiber leather is generally considered more eco-friendly than genuine leather.

It requires a different amount of water, land, and energy to produce.

Often made from recycled materials, which reduces its environmental impact.

Faux Leathers demonstrates environmental responsibility by choosing processes that conserve water. This approach supports sustainability and helps protect natural resources for future generations.

Energy Use

The energy required to produce microfiber leather is significantly lower than that needed for genuine leather. Traditional leather processing involves energy-intensive steps such as curing, drying, and chemical treatments. Microfiber leather manufacturing uses advanced techniques that streamline production and reduce energy consumption. Many factories now use renewable energy sources, which further supports sustainability goals.

Microfiber materials also benefit from efficient production lines. These lines optimize energy use and minimize waste. As a result, microfiber leather stands out as a sustainable and eco-friendly choice for manufacturers and consumers alike.

Low Emissions

Cleaner Production

Microfiber leather manufacturing produces fewer emissions than traditional leather processing. The industry has adopted tightly controlled processes that use bio-based feedstocks and optimized curing techniques. These improvements help lower the carbon footprint of microfiber products.

Aspect

Details

Emission Profile

Low carbon microfiber leather has a significantly reduced carbon emission profile compared to traditional hides.

Manufacturing Techniques

Tightly controlled processes leverage bio-based feedstocks and optimized curing techniques.

Environmental Practices

Producers are investing in solventless bonding and renewable energy sourcing to minimize emissions.

Monitoring and Optimization

Advanced analytics platforms are used to monitor energy consumption and material waste in real time.

Faux Leathers supports cleaner production by investing in modern technology and sustainable practices. These efforts align with the brand’s commitment to sustainability and environmental responsibility.

Fewer Chemicals

Traditional leather tanning often uses harsh chemicals, which can harm the environment. Microfiber leather production avoids many of these substances. Manufacturers use water-based polyurethane coatings and safer dyes. This reduces the risk of pollution and makes microfiber leather a safer, more sustainable material.

Many factories also monitor chemical use closely. They follow strict guidelines to ensure that microfiber products remain safe for both people and the planet. This focus on fewer chemicals supports the eco-friendly reputation of microfiber leather.

Durability

Long Life

Microfiber leather offers impressive durability. The normal service life of general microfiber leather is 5-10 years. High-quality microfiber leather may last even longer. This long lifespan means that products made from microfiber require fewer replacements, which supports sustainability.

Microfiber leather is generally more durable and easier to care for than genuine leather.

Genuine leather may require more maintenance to keep it in good condition.

Microfiber leather is more resistant to stains and water damage, making it easier to maintain.

Faux Leathers designs its microfiber products to withstand daily use. Customers benefit from materials that look great and last for years.

Less Waste

Durable materials like microfiber leather help reduce waste. Because microfiber products last longer and resist damage, fewer items end up in landfills. This durability supports a circular economy, where products stay in use for as long as possible.

Microfiber leather typically lasts between 5 to 10 years.

Genuine leather can last much longer with proper care.

Microfiber leather is more resistant to stains and water damage, making it easier to maintain.

Sustainability remains a core value for Faux Leathers. By offering long-lasting microfiber leather, the brand helps customers make eco-friendly choices that benefit the environment.

Animal-Free

No Animal Products

Microfiber leather offers a clear advantage for those who care about animal welfare. Manufacturers create this material from artificial components, such as polyurethane and ultra-fine microfiber, instead of animal skin. This process ensures that no animals are harmed or exploited. Many organizations, including PETA, recognize microfiber leather as a vegan-friendly alternative. People who choose microfiber leather support a cruelty-free lifestyle and help reduce the demand for animal-based products.

Microfiber leather is made from synthetic materials, not animal hides.

The production process does not involve animal cruelty or exploitation.

Vegan-friendly options appeal to eco-conscious consumers.

PETA lists microfiber leather as a responsible choice with a lower environmental impact than genuine leather.

Faux Leathers demonstrates a commitment to ethical manufacturing. The brand’s microfiber products align with the values of customers who want to avoid animal-derived materials.

Biodiversity

The production of microfiber leather helps protect biodiversity. Traditional leather relies on cattle ranching, which causes widespread deforestation and habitat loss. Microfiber leather uses synthetic fibers and polyurethane, so it does not contribute to these environmental problems. The shift away from animal-based leather supports the preservation of forests and wildlife.

Activity

Impact on Biodiversity

Cattle ranching in the Amazon

80% of deforestation, significant biodiversity loss

Cattle production in Queensland, Australia

73% of deforestation, endangerment of species

Land cleared for Brazilian leather bags

Habitat destruction

Land cleared for leather boots

Increased risk of desertification

Microfiber leather production does not require large-scale land conversion. Millions of acres in South America are cleared each year for cattle, leading to soil erosion and increased fire risk. By choosing microfiber, manufacturers and consumers help protect natural habitats and reduce threats to endangered species.

Note: Microfiber leather supports biodiversity by reducing the need for cattle ranching and deforestation.

Faux Leathers continues to innovate with animal-free materials. The brand’s focus on microfiber solutions helps customers make choices that benefit both animals and the environment.

Microfiber Leather vs. Genuine Leather

Environmental Impact

When comparing microfiber leather and genuine leather, the environmental differences become clear. Microfiber leather production uses synthetic fibers and polyurethane, which means it does not rely on animal raw materials. This process helps reduce the demand for livestock farming, a major source of greenhouse gas emissions and deforestation. Genuine leather, on the other hand, comes from animal hides. Raising livestock for leather requires large amounts of land, water, and feed. It also produces methane, a powerful greenhouse gas.

Microfiber leather manufacturing uses less water than traditional leather tanning. The process avoids the harsh chemicals found in animal leather tanning, which often pollute water sources and harm local ecosystems. However, microfiber leather does use petrochemical-based materials. These materials require energy and resources to produce, and they are not biodegradable. Despite this, many manufacturers, including Faux Leathers, use recycled materials and water-based coatings to lower the environmental impact.

Microfiber leather production uses fewer animal raw materials, making it more environmentally friendly than genuine leather.

Genuine leather is biodegradable but involves chemicals in tanning and emissions from livestock.

Microfiber leather manufacturing avoids water pollution linked to animal leather tanning.

Faux Leathers continues to improve its processes by investing in cleaner production methods and sustainable sourcing. The brand’s microfiber products offer a responsible choice for those who want to reduce their environmental footprint.

Ethics

Ethical concerns play a major role in the choice between microfiber and genuine leather. Microfiber leather is a vegan material. It does not use animal products or by-products. This cruelty-free approach appeals to consumers who care about animal welfare. Faux Leathers’ microfiber leather supports a vegan lifestyle and helps reduce the demand for animal agriculture.

Animal-based leather production raises several ethical issues. It involves raising and slaughtering animals, which many people find unacceptable. The process also contributes to water pollution and greenhouse gas emissions. The chemicals used in tanning animal hides can prevent biodegradation and pollute local environments.

Faux leather, including microfiber leather, is cruelty-free and does not use animal products.

It reduces the environmental impact linked to traditional leather production, which is associated with animal agriculture.

Animal-based leather production contributes to significant water pollution and greenhouse gas emissions.

The tanning process for animal leather involves harmful chemicals that prevent biodegradation and pollute local ecosystems.

Faux Leathers’ commitment to ethical manufacturing sets it apart. The brand’s microfiber leather provides a superior alternative for those who value both sustainability and animal welfare. By choosing vegan materials, consumers support a more ethical and environmentally conscious future.

Microfiber Leather vs. Vegan Leather

Material Sources

Microfiber leather and vegan leather both offer animal-free alternatives to traditional leather. However, their sources differ. Microfiber leather uses ultra-fine synthetic fibers, such as polyester or nylon, combined with a polyurethane coating. This structure gives it a leather-like feel and appearance. Manufacturers often use recycled materials in microfiber production, which helps reduce waste.

Vegan leather, on the other hand, comes from a variety of plant-based or synthetic sources. Some types use natural materials like pineapple leaves, cactus, or grape skins. Others rely on synthetic polymers. The choice of raw material affects the final product’s texture, durability, and environmental impact. Faux Leathers provides both microfiber and vegan leather options, allowing customers to select the best fit for their needs.

Note: The source material plays a key role in the sustainability and performance of each leather alternative.

Performance

Performance varies between microfiber leather and vegan leather, depending on their composition. Microfiber leather stands out for its high durability. It resists wear and tear, making it suitable for products that face daily use, such as bags, upholstery, and sports equipment. Its water and stain resistance add to its appeal, especially for items that require easy cleaning.

Vegan leather performance depends on the specific type. Some plant-based leathers offer good durability, while others may be more prone to staining or water damage. The versatility of vegan leather also varies. Certain types work well for fashion accessories, while others suit automotive or interior design applications.

The table below highlights key differences:

Feature

Microfiber Leather

Vegan Leather

Durability

High; withstands wear and tear

Varies; generally durable but depends on type

Water Resistance

Yes; water-resistant

Varies; some types may not be water-resistant

Stain Resistance

Yes; stain-resistant

Varies; some types may stain easily

Versatility

Suitable for bags, clothing, upholstery

Varies; depends on specific vegan leather type

Environmental Impact

Involves petroleum-based products

Generally lower impact, but varies by type

Breathability

Less breathable than genuine leather

Varies; some types may be more breathable

When considering sustainability, both materials offer advantages over animal leather. Microfiber leather and vegan leather avoid methane emissions and chemical waste linked to traditional tanning. Recent advancements in eco-friendly production methods continue to improve their environmental profiles. The carbon footprint of artificial leather, including microfiber, is much lower than that of cow skin leather. For example, artificial leather has an impact of about 15.8 kg of CO2e per square meter, while cow skin leather reaches 110.0 kg of CO2e per square meter. Water use also differs greatly. Leather production can require over 17,000 liters of water for a single tote bag, while synthetic and plant-based alternatives use far less.

Both microfiber leather and vegan leather reduce the need for animal agriculture.

Manufacturers continue to develop more sustainable options for both materials.

The total environmental impact depends on the entire lifecycle, from raw material extraction to disposal.

Faux Leathers offers a range of microfiber and vegan leather products. Customers can choose based on their priorities, whether they value durability, sustainability, or versatility.

Real-World Impact

Recycling

Microfiber leather offers practical solutions for end-of-life management. Many manufacturers design microfiber leather to be recyclable. They use synthetic fibers and polyurethane coatings that can be separated and processed for reuse. Recycling helps reduce landfill waste and supports a circular economy. Some companies collect used microfiber products and send them to specialized facilities. These facilities break down the material and recover valuable components.

Consumers can extend the life of microfiber leather by choosing products with durable construction. Faux Leathers encourages customers to care for their items and consider recycling options when products reach the end of their useful life. Many local recycling centers accept synthetic materials. Some brands also offer take-back programs for used bags, upholstery, or accessories. These programs help keep valuable resources in use and reduce environmental impact.

Tip: Proper cleaning and maintenance can extend the lifespan of microfiber leather, making recycling less frequent and more effective.

Microfiber leather resists stains and water damage, which means products last longer. This durability reduces the need for frequent replacements. When items do wear out, recycling provides a responsible way to manage waste. The process supports sustainability and helps conserve natural resources.

Certifications

Certifications play a key role in ensuring the safety and sustainability of microfiber leather. Faux Leathers meets several important industry standards. These certifications confirm that products are free from harmful substances and produced using eco-friendly methods.

Certification

Description

ROHS

Restriction of Hazardous Substances

EU REACH

Registration, Evaluation, Authorisation and Restriction of Chemicals

EN20345

European Standard for safety footwear

Manufacturers follow strict guidelines to achieve these certifications. ROHS restricts the use of hazardous materials in production. EU REACH regulates chemicals to protect human health and the environment. EN20345 sets safety standards for footwear, ensuring products meet high performance requirements.

Industry standards also support sustainability. The following table shows how these standards impact microfiber leather production:

ISO Standard

Purpose

Impact on Sustainability

ISO 9001:2015

Enhances quality management systems

Improves product quality

ISO 14001:2015

Demonstrates commitment to environmental management and sustainability

Ensures eco-friendly practices

ISO 45001:2018

Ensures worker safety during production processes

Promotes safe working conditions

ASTM Testing

Assesses colorfastness, water absorption, and area stability

Ensures product durability and safety

Harmful Substances

Certification process checks for over 1,000 harmful substances

Reduces environmental and health risks

These standards require regular testing and monitoring. Manufacturers assess colorfastness, water absorption, and stability to guarantee product safety. Certification processes check for more than 1,000 harmful substances, reducing risks to people and the planet.

Faux Leathers demonstrates a commitment to quality and sustainability by meeting these certifications. Customers can trust that microfiber leather products align with global safety and environmental standards. This approach supports responsible manufacturing and helps build a more sustainable future.

Applications

Microfiber leather products have transformed many industries with their durability, versatility, and eco-friendly qualities. Designers, manufacturers, and consumers now rely on these materials for a wide range of uses.

Fashion

Fashion brands have embraced microfiber leather products for their ability to mimic the look and feel of genuine leather while offering superior performance. Designers use these materials to create stylish handbags, shoes, jackets, and accessories. The lightweight nature of microfiber leather products makes them comfortable for daily wear. Many brands choose these materials for their resistance to stains and scratches, ensuring that items maintain their appearance over time.

Handbags

Shoes

Jackets

Accessories

Microfiber leather products allow for a variety of colors and textures, giving designers creative freedom. Customers appreciate the easy maintenance and long-lasting quality. Faux Leathers supplies fashion houses and independent creators with materials that support sustainable practices.

Note: Microfiber leather products in fashion combine style, comfort, and sustainability, making them a preferred choice for eco-conscious consumers.

Automotive

Automotive manufacturers increasingly use microfiber leather products for vehicle interiors. These materials cover seats, dashboards, and trims, providing a luxurious feel without the environmental impact of traditional leather. Microfiber leather products offer high tear and peel strength, ensuring longevity in high-wear areas. Their abrasion resistance keeps car interiors looking new, even after years of use.

Seats

Dashboards

Interior trims

Microfiber leather products contribute to improved fuel efficiency due to their lightweight properties. Car owners benefit from interiors that resist stains and spills, making cleaning simple. The material does not peel or age quickly, maintaining a pristine condition. Many leading car brands have adopted microfiber leather products for their superior durability and environmental performance.

Feature

Benefit

Tear/Peel Strength

Ensures longevity

Abrasion Resistance

Suitable for high-wear areas

Lightweight

Improves fuel efficiency

Stain Resistance

Enhances practicality

Home & More

Microfiber leather products have found a place in homes and other industries. Furniture makers use these materials for upholstery, offering a synthetic alternative that is easy to clean and maintain. Homeowners enjoy sofas and chairs that resist stains and wear. Microfiber leather products also appear in bags, wallets, and clothing, providing affordable and durable options.

Bags and wallets

Clothing, such as jackets and pants

Furniture upholstery

Sports equipment, including gloves and shoes

Electronics cases for phones and tablets

Luggage and pet beds

Sports equipment manufacturers rely on microfiber leather products for moisture-wicking and abrasion resistance. Electronics cases made from these materials protect devices from scratches. Faux Leathers supports a variety of industries by supplying microfiber leather products that meet diverse needs.

Tip: Microfiber leather products offer practical solutions for everyday life, from furniture to sports gear.

Customer stories highlight the satisfaction with microfiber leather products. Decorative Fabrics Direct, for example, provides upholstery fabrics that maintain quality and appearance, even with frequent use. Many customers praise the durability and easy care of these materials in both residential and commercial settings.

Challenges & Future

Market Trends

The microfiber leather industry continues to evolve as new market trends shape its future. Sustainability stands out as a major driver. Consumers and manufacturers seek eco-friendly production processes and bio-based materials to lower the carbon footprint. Technological innovation leads to improved tactile properties and surface textures that closely resemble genuine leather. Customization has become more accessible through digital printing and advanced surface finishing, allowing tailored products for individual preferences.

Smart textiles represent another growing trend. Manufacturers integrate IoT features into products, enhancing user experience in automotive and luxury fashion sectors. E-commerce growth also influences the market. Direct-to-consumer channels provide increased access and encourage innovation.

Trend

Description

Sustainability

Strong demand for eco-friendly production processes and bio-based materials.

Technological Innovation

Advancements in tactile properties and surface textures that mimic genuine leather.

Customization

Digital printing and surface finishing innovations enable tailored products for consumers.

Smart Textiles

Integration of IoT features in products, enhancing user experience in automotive and fashion.

E-commerce Growth

Increased market access and innovation driven by direct-to-consumer channels.

Faux Leathers responds to these trends by offering microfiber leather solutions that meet the needs of modern consumers. The brand focuses on sustainability, customization, and advanced technology to stay ahead in the market.

Innovation

Innovation drives the microfiber industry forward. Manufacturers now use recycled materials and develop biodegradable products to reduce environmental impact. Antimicrobial properties have become important, especially in healthcare settings. Microfiber leather infused with antimicrobial agents helps combat cross-contamination risks. These materials improve hygiene and patient comfort in medical furniture.

Recent advancements include self-healing surfaces and smart solutions. IoT integration allows products to interact with users, adding value in automotive and luxury fashion applications. The market expands beyond traditional uses, with microfiber leather now playing a role in public health resilience.

Faux Leathers leads the way in microfiber leather technology. The brand supports environmental sustainability by promoting eco-friendly alternatives to traditional leather. Ethical consumerism increases demand for cruelty-free products, positioning microfiber as a responsible solution. Technological advancements enhance quality and performance, making synthetic leather more appealing. Regulatory support encourages adoption through policies that promote sustainable practices. Cost-effectiveness offers long-term savings due to durability and low maintenance.

Factor

Contribution to Microfiber Leather Development

Environmental Sustainability

Drives demand for eco-friendly alternatives.

Ethical Consumerism

Increases demand for cruelty-free products.

Technological Advancements

Enhances quality and performance.

Regulatory Support

Encourages adoption through sustainable policies.

Cost-Effectiveness

Offers long-term savings and durability.

Note: Faux Leathers continues to invest in research and development, ensuring that microfiber leather remains at the forefront of innovation and sustainability.

Microfiber leather stands out as a sustainable alternative for eco-conscious consumers. The material addresses ethical concerns and reduces environmental impact. Faux Leathers offers innovative microfiber solutions that combine durability and style. The table below highlights the main eco-friendly advantages:

Key Takeaway

Description

Sustainable Alternative

Microfiber leather appeals to environmentally conscious consumers.

Ethical Considerations

The material supports animal rights and reduces environmental harm.

Environmental Impact

Microfiber production lowers pollution compared to traditional leather.

Innovative Materials

Advancements in biomanufacturing enhance eco-friendly profiles.

Consider microfiber for your next project or purchase. Explore Faux Leathers’ offerings to support sustainability and style.

FAQ

What is microfiber leather made of?

Microfiber leather contains ultra-fine synthetic fibers and a polyurethane (PU) coating. Manufacturers weave the fibers into a dense base, then apply the PU layer for durability and a leather-like appearance.

How do you clean microfiber leather?

Use a damp cloth and mild soap to clean microfiber leather. Avoid harsh chemicals. Regular cleaning helps maintain the material’s appearance and extends its lifespan.

Is microfiber leather environmentally friendly?

Microfiber leather supports sustainability. It uses fewer resources than genuine leather and avoids animal products. Many manufacturers, including Faux Leathers, use recycled materials and water-based coatings to reduce environmental impact.

Can microfiber leather be recycled?

Many microfiber leather products are recyclable. Manufacturers design them for easy separation and processing. Recycling helps reduce landfill waste and supports a circular economy.

Where can you use microfiber leather?

Microfiber leather works well for bags, shoes, upholstery, automotive interiors, and sports equipment. Its durability and versatility make it suitable for many industries.

What certifications does Faux Leathers’ microfiber leather meet?

Faux Leathers’ microfiber leather meets standards like ROHS, EU REACH, and EN20345. These certifications confirm safety, quality, and eco-friendly production.

How long does microfiber leather last?

High-quality microfiber leather lasts 5 to 10 years or more. Its resistance to stains, scratches, and fading ensures products remain attractive and functional over time.

Is microfiber leather animal-free?

Microfiber leather contains no animal products. Manufacturers use synthetic fibers and polyurethane, making it a vegan-friendly and cruelty-free choice.